Aluminum is used in almost every industry and a household item. In addition to being abundant, light, and able to bond easily with oxygen, aluminum is usually used in medicines, package materials, interior construction, automobiles, trains, and airplanes.

That is why aluminum was chosen as an outer material of the spacecraft because it is both strong and light. Obtaining deep drilling experience using aluminum also requires a few tools that you’ll already know after completing this project.

Things you Need

- Pipe made of aluminum

- Pen or marker

- Vises for clamping

- An electric drill

- The bit for drilling

- Liquid dishwashing

Ensure that the Bits are Lubricated

Moreover, it is advisable to always choose lubricated bits when it comes to flat metal brackets and other such fittings and fixtures. It is especially important to do this when drilling holes in steel and iron that are more than 1/8 inch thick.

It’s important to choose the right lubricating oil, such as 3 in 1 lubricating oil. As a result, friction will be significantly reduced and excessive heat will be prevented. In addition to this, drilling will get easier with this as well and bits will be much more durable and able to last a long time. It would be unnecessary to lubricate metals such as cast iron, brass, or aluminum that are easier to drill.

Make Sure your Eyes are Protected

- You need to consider all the risks involved with drilling through aluminum while you are interested in finding the right solution.

- The metal fragments that cause eye injuries are so tiny that even very small ones can cause serious issues. Thus, safety precautions should be taken to protect the eyes when drilling metals.

- Safety glasses need to fit your face as well as your eyes, and you must select the best ones that will not only protect the eyes but also offer side face protection.

Steps for Drilling through Aluminum

You can drill into aluminum by following these simple steps:

Step 1: Mark the Area

In order to drill the aluminum pipe, first, mark the area where you will drill. This will make it easy for you to do the drilling task if you mark it in a clear and visible manner. When writing on aluminum, a marker pen is preferred, because it has a greater chance of being visible.

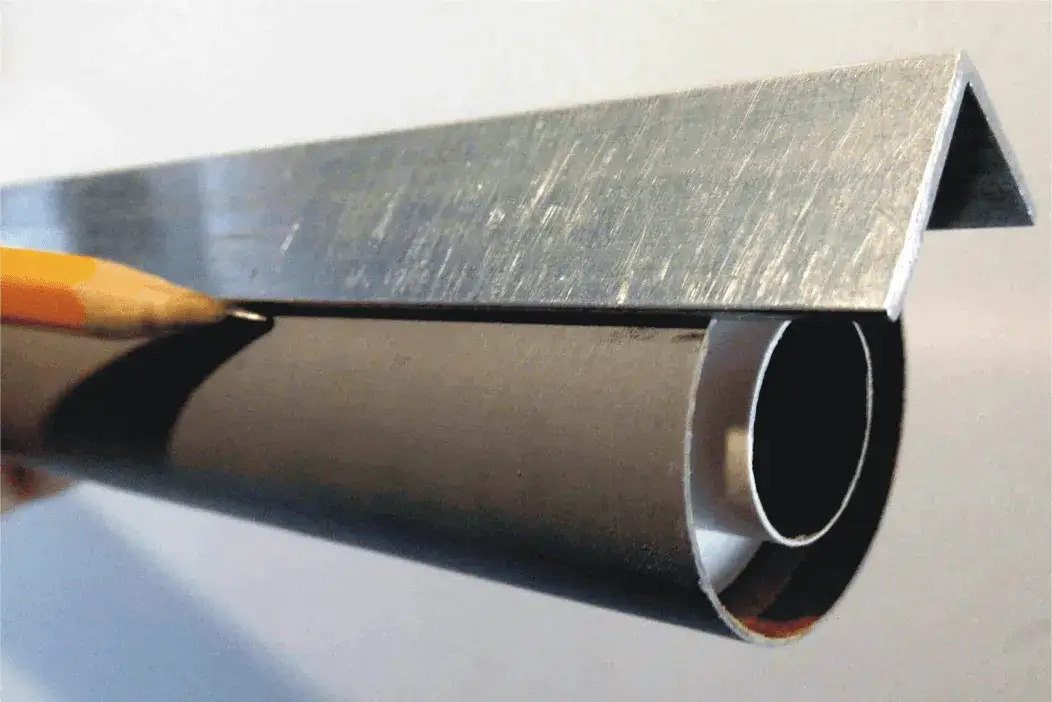

Step 2: Secure the Aluminum Pipe

It is necessary to secure the aluminum pipe in a secure location, such as a vise so it can hold the aluminum pipe. Your mark must be easily accessible and must not be covered by the clamp vise.

Step 3: Make a Starter Hole

Once you have the drill fitted with an appropriately small bit, you will need to drill the aluminum pipe with that bit. A starter hole can be made using this bit when it is used on the step.

Step 4: Lubricate the Aluminum Pipe

Then you can lubricate the aluminum pipe by rubbing some dishwashing liquid on the mark you made earlier. Ensure that the tip of the bit is covered with liquid.

Step 5: Start Drilling

Once you have marked the aluminum pipe, take your drill and start drilling until the bit manages to exit the other side of the aluminum pipe. It is possible to drill into the aluminum pipe only through one side, but as soon as you have punched through it, stop drilling.

Step 6: Replace the Bit with Step Bit

Once that is done, now you will need to replace the regular bit and replace it with the step bit you have selected. Ensure that you apply dish soap to your entire bit and also put on more soap on the aluminum pipe around the edges of your drilled starter hole.

Step 7: Drill again into Starter Hole

Last but not least, you will need to insert the tip of the step bit into the starter hole and drill through it so that it is widened appropriately. The bit must be driven at a low speed and patience is required as you wait for it to work its way through the aluminum pipe.

Frequently Asked Questions

Conclusion

However, you have to be cautious when drilling through aluminum even though it’s relatively easy to work with. Additionally, it is highly pliable and lightweight, so it can be recycled over and over again, regardless of its state. It is not designed to penetrate such materials, so most drill bits tend to either become dull or actually eat through the material and ruin your project.